April 10, 2025 | Important Announcement

Dear Friends and Fellow Travelers:

This year marks the 40th year of operation for Bowen Classic Arms Corporation. We have had a great run.

I am of retirement age now with aging eyes and a failing shoulder which makes meeting the physical demands of benchwork and shooting increasingly difficult. Accordingly, effective June 1st, we will no longer accept orders for custom revolver work. While the sight and parts business will carry on, we expect to wind down the shop work on hand by year’s end or as soon as practicable. We will do our best to make the process as smooth as possible but please bear with us.

In the near term, shop business will continue as usual. However, bear in mind some of our vendors—most notably our old friends at Turnbull Restorations—are extremely busy, too. We cannot accept orders that involve color case hardening since it will be very difficult to finish such projects by year’s end. Most of our friends in the grip-making trade are also quite busy so we will advise on a case-by-case basis if we can accommodate their grip work prior to delivery of our work. Most professional grip makers work on finished guns so this should not materially affect the final results—we simply will not have a hand in the logistics—customers will take delivery of completed guns from us and the pursue the grip work on their own. In any event, it is imperative that you do not send along project revolvers without first contacting us to discuss the job.

Our hope is to continue in the trade as parts suppliers and pursue some writing projects. I would like to thank all of our friends and loyal customers for their patronage and support over the years. It has been a pleasure to share our handiwork with you.

With thanks and best wishes,

Hamilton S. Bowen

Bowen Classic Arms Corp.

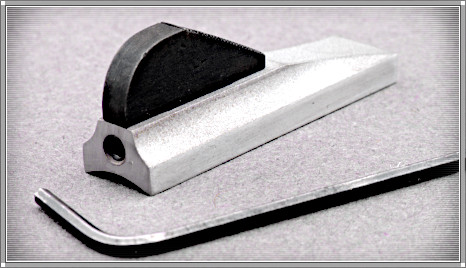

March 11, 2024 | NEW FRONT-SIGHT SYSTEM— We have struggled for years with detachable-blade front sight set-ups and have found them all wanting for various reasons. The Old Dan Wesson arrangement worked well enough but had a cross pin in the rib and a tiny retaining screw. The excellent Freedom Arms arrangement works very well but is not compatible with integral installations. The S&W DX system works pretty well if you have fingers like vise-grips but also requires a cross-pin in the design. We needed something that required only machine work from the top and front, free of cross pins and user friendly.

Our sight arrangement is adaptable to most revolvers by various means. Operation is simple, just like most of the rest of the screw-retained systems in use now. Simply loosen the lock screw at the muzzle of the sight base, wind it out a few turns and lift the blade up and out. Blades are somewhat like the DX-type which may in some cases be adaptable to our bases. It is simple, hardy and uncluttered.

We’ll have a simple solder-on base for single-action revolvers reminiscent of our old house, custom sight suitable for standard round barrels (see photo). We also expect to have screw-on bases for double-action revolvers where barrels are shortened and a new sight installation necessary. The foot-print and layout will be the same and compatible with our current DX double-action bases for both S&Ws and Redhawks, fitting existing machine-work if one cares to update to the new type—it will drop right on without additional machine work. We plan to supply these along with blade blanks. Common blade patterns and heights will follow in due course.

More importantly, this new set-up is readily machined into our custom Smith & Wesson and octagonal single-action barrels (see photo). It is also compatible with the L-frame and SP-style double-action barrels we produce. While we have modified the factory front-sight installations on Ruger Blackhawk barrels, appearance isn’t the best so this is not currently a likely offering. As a general observation, the installation may be performed on certain S&W barrels with integral blades.

We’re working to update and overhaul our website and shopping cart and will have entries for these parts as time and inventory permit.

September 6, 2022 | THE LATEST AFFRONT TO GUN OWNERS BY UPS— The Gun Control Act of 1968 largely prohibited the movement of firearms between private parties via the US Mail and various common carriers such as UPS and FDX. After 1968, the US Post office permitted mailing of firearms only between dealers. There was one exception. Common carriers could still lawfully convey between gun owners and factory service departments and gunsmiths rifles, shotguns and handguns, ordinary firearms unencumbered by the National Firearms Act of 1934. These shipments were made by both ground and air with several levels of service.

In 1999, UPS commenced their war on firearms owners, especially handgun owners, by requiring all handguns accepted for shipment to travel exclusively via UPS Next-Day Air service at great expense. UPS claimed it must do so for ‘security reasons’. Secured from whom, you might ask. Yes, UPS vehicles were occasionally hi-jacked or breached in the field but significant numbers of firearms were simply looted from UPS depots by UPS employees. Whether overnite shipping of handguns materially cut theft rates isn’t clear. What is clear is handgun owners have taken it in the financial shorts for decades because UPS could not evidently protect goods entrusted to it.

For reasons that appear to have little to do with security, UPS and co-conspirator FDX have loosed another broadside. Apparently, both will now permit (no confirmation yet) handgun shipments only between FFL holders. Clearly, the change in consignor and consignee merely changes the label with no bearing on security, reducing exposure to theft, internal or otherwise. To an outside observer, one might conclude that UPS and FDX are colluding with the US Govm’t. as state actors to play policemen and wage proxy war on gun owners on a second front. Regardless, the net effect now is the cost to handgun owners, not only of the usual $200 — $300 in round-trip tickets via Air OOPS but also now not one but two FFL holders involved in the transaction. Handling the gun and related administrative costs can total $50 —$100 at usual shop rates, especially if NICS checks are involved. Also may impose considerable extra time and travel for a the gun owner has to travel a great distance to a dealer or depot. In short, those of us who own and ship our handguns via UPS are getting plundered for fun and profit. Not to be left out of this bonanza, FDX bravely signed on to lend a hand in the financial beatings.

Dealers and gunsmiths who wish to continue UPS service are required to sign a contract that creates three separate accounts: for 1.) guns, 2.) for gun parts/accessories and 3.) and all other stuff, all maintained, naturally, weekly at considerable expense whether used or not. And that is just the least of it. Despite our several efforts at clarification, we still do not know whether or not UPS will recognize the exception in the Federal law for shipments to factory service departments or gunsmiths. In any event, until further notice, all return shipments from Bowen Classic Arms Corp. will be via USPS to your friendly local dealer. Best to plan accordingly. For those of you with firearms already in our care, please send along an FFL so we can ‘lawfully’ return your property.

For anybody suffering from enemy-identification problems, this should help. Just my opinion. More to follow as developments develop. HSB

January 1, 2020 | THE JOHN GALLAGHER FUND—Most of us pass through life within a group of like-minded fellow travelers, all about the same ages. Many of these people we meet in our various professions and careers. Some end up not only as business associates but close friends. As you near retirement age, a lot of these friendships start to date back 25–30 years or more. Ben Forkin, John Linebaugh, John Gallagher, Thad Rybka and Ashley Emerson and me are all roughly the same age, now in our 60s, give or take a year or three and have all mostly plied the gun trade some way or other for most of our adult lives. There are many others in this class but this is the part of the cohort I’ve known longest. Which makes it all the more painful to see one of these old friends afflicted with some catastrophic health problem from out of nowhere.

John Gallagher has been struggling with cancer for some years now. While we’re all holding out for a miracle, the issue is very much in doubt. What isn’t in doubt is the terrible burden of the uncertainty, worry for his family and of the loss of time in the shop where a living gets made. John is a taciturn, proud, independent, resourceful man, to say nothing of a gifted gunmaker. His rifles and revolvers are legendary. He is not one to toot his own horn or make a fuss. He could use a hand so his friends are going to toot it and make a fuss for him.

And it is not just the few of us. John has friends in every customer he has ever had. He has friends in everyone who he has helped on the phone, giving freely and unreservedly of his time and expertise. He has friends in all who admire and respect his great talent. Many of these fine folks have already made considerable efforts on John’s behalf but some of you reading this still may not know of his circumstances and may wish to throw in with the rest of us.

This fund is established to that end and is overseen by our friend John Taffin, a familiar presence in these pages for decades. He has agreed to receive cards and donations from well-wishers and anonymous contributions, as well. The former may be addressed/made to Mr. and Mrs. John Gallagher and will be forwarded as they arrive in John Taffin’s hands. Anonymous contributions will be pooled in a special account and lump sums sent periodically. In this instance, checks should be made to The John Gallagher Fund. If you have any questions, please contact John Taffin at 6410 West Pomona Road, Boise, ID 83704; jtaffin@outdrs.net or Hamilton S. Bowen via shop@bowenclassicarms.com.

John is a great American and the kind of guy you would want to have your back. Here is a chance for us to have his. Our heartfelt thanks to all who are able to help out or simply keep the Gallaghers in their thoughts and prayers.

December 13, 2018 | Anaconda Barrels—We have been lucky enough to acquire a number of .45 Colt Anaconda barrels. Anaconda barrels have become quite scarce in the last few years, and unfortunately the market price for them has grown accordingly. These factory barrels can be cut and mated to either standard Ruger Redhawks or utilized in a GP conversion on a Super Redhawk Alaskan. We will be cataloging this offering until the supply of barrels is exhausted. Please see Cat. No. RD03 in the Ruger double-action basic packages section of the catalog for more details

February 13, 2018 | NEWS UPDATE —We are caught up a bit so are now accepting orders for line-bored 5-shot large-frame caliber conversions and have a fair stock of parts at hand. We expect by Spring to have 6-shot cylinders in good supply and will be able to produce again most all of our usual catalog offerings. Thanks for your patience.

February 9, 2017 | Cylinder Shortage —Effective March 15th, we will no longer be able to accept the more complicated line-bored caliber conversions until we are caught up on these. With our current workload, we are simply too far behind on such projects at this time to accept more. The more basic single-action packages are welcome and we hope to be able to speed up delivery on this sort of work this spring.

March 15, 2016 | CATALOG REVISION — Effective May 1st 2016, we will no longer accept S&W revolver projects and will take down the S&W catalog section. A great many of our S&W offerings involve barrel work, particularly sight and caliber conversion. More and more of the newer guns have barrels set so tightly that the factory service department refuses to remove them because of the risks of receiver damage. Unfortunately, it is impossible to know when guns are suitable candidates for barrel removal until you put a barrel wrench to one. Due to the untimely loss of friend and colleague Jim Dubell who did our reboring, we also have a considerable backlog of S&W caliber conversions to address as we are able to get barrels rebored; these are our top priority. We also expect to concentrate more on our parts business. With a couple of new machine shops hard at it now on our behalf, the sight and part situation is improving which will enable us to bring on line some needed new sight parts.

August 25, 2015 | PARTS DELAYS—As many of you who have tried to order parts from us in the last couple of years know too well, we have not been able to dependably inventory and deliver many of our parts, especially rear sights. For the last twenty or twenty-five years, we have utilized the services of a great, old family-owned machine shop founded in 1940 to do the rough-out machine work on most of our parts. Sadly, in their seventy-fifth year of operation, this company appears to be failing, most likely victims of a lousy economy, off-shore competition, an unwilling local work force and a fractious family management or some unholy combination of the above. Nobody has ever accused the management at Bowen Classic Arms of a firm grasp of the obvious but, even for us, it is apparent time has run out. Accordingly, we are on the warpath to ferret out some other machine shops, especially gun-industry related ones, in hopes of starting part production afresh elsewhere. We have one under contract in MA and are awaiting quotations from another in MT. Another in AL is in the crosshairs. It is our hope to put the worst of this mess behind us by year’s end but we have a ways to go yet. We have to purchase new tooling, the shops will have to produce some fixtures which will take some time and we’ll have to prioritize production. Even once we have dependable suppliers again, we have a considerable backlog of orders to fill. In any case, we appreciate very much your patience and forbearance with us. You may rest assured we will do our damnedest to see orders filled again on a timely basis.

July 13, 2015 | Rebored Barrels—Sadly, there are some unwelcome changes coming. With the untimely death of my friend and colleague Jim Dubell, owner of Delta Gun Shop and Clearwater Reboring, effective immediately, we can no longer accept orders for projects involving rebored barrels. There is a chance his reboring equipment will soldier on in the capable hands of a former employee. We will advise as events unfold.

January 12, 2015 | Price Changes— As much as we hate to do it, we must raise our prices on some services, effective immediately. Unfortunately the costs associated with many parts and services used in the normal course of our work have escalated considerably in the last couple of years. We hope and trust our friends and customers will understand and bear with us.

November 27, 2014 | New Redhawk Barrels— There are a new generation of short barreled Ruger Redhawks which are not compatible with certain modifications. The new-style 2-3/4" and 4" Ruger Redhawk barrel with traditional detachable front sights are not compatible with a DX front sight base conversion.

April 8, 2014 | Non-Catalog Parts— There are many parts we produce in the course of our work which are not part of the standard catalog for sale on the website. Our non-catalog parts are those of a specialized nature which require special skills and tooling to employ, and as such can be ruined in attempts to install. As of this writing any non-catalog parts sold will be nonreturnable and must be prepaid by check.

April 1, 2014 | No Sales into Maryland— Due to recent changes in legislation, we can no longer sell any firearms for delivery into the state of Maryland. New legislation should not preclude customers from the state of Maryland from soliciting custom work on their own firearms, please consult state and local statutes before submitting any work.

October 19, 2013 | Bisley Hammers— Unfortunately, at this time, Ruger has discontinued production of New Model blue Bisley-spur hammers. These parts are quickly becoming unobtainable and we are currently out of stock. This affects a wide variety of catalog items and options. In certain cases stainless steel hammers can be substituted.

June 18, 2013 | Catalog Revision— Anyone subject to today’s economy and political climate appreciates the distortions of the otherwise staid and stolid firearms sector. Paradoxically, the economy is struggling but we (Bowen Classic Arms) are also overwhelmed with work. Part of the problem is, when the economy tanks, some firms reduce workforces or loose critical employees which means, in turn, they are then unable keep up with remaining demand on their products and services. In other cases, fear induced by political uncertainty causes panic buying which, in turn, results in unnatural scarcity of important components used in the broader industry. All of which taxes our capacity to deliver our work in a timely manner.

There is not much we can do to change the composition of our staff in the short term nor can we command the heavens to supply us with critical parts, reboring or test-fire ammunition. Accordingly, we are making a few small adjustments to our catalog to improve service and shorten delivery times on core offerings. Effective immediately, we will no longer accept work involving J-frame S&W's, Ruger Bearcats and SP101's until further notice, including the following catalog offers:

* SW04 J-frame Hi-Visibility Sight Installation

* BC01 ‘Standard Issue’ Bearcat

* BC02 ‘Perfected’ Bearcat

* RDSP101 ‘Perfected’ SP101

Work on any of these projects already in house will be delivered in the course of our normal work rotation.

Please note: We would encourage anyone interested in these services to contact a couple of our friendly competitors for assistance. Dave Clements performs some very tasteful Ruger Bearcat conversions, and Cylinder & Slide has agreed to take on the installation of our Fixed J-Frame/SP101 Sights.

![]()

Our good friend Jim Dubell of Delta Gun Shop is also working mightily to speed up delivery of rebores which will help man of our caliber conversions. We’ll continue to accept projects requiring reboring but will ask your continued patience and indulgence since we have a considerable backlog of work at hand to retire before any real improvement in delivery will trickle down. We are also in regular communication with our sight parts vendor to keep parts moving as quickly and often as possible.

Our best hope for returning to normal, whatever that really is, depends most on a favorable change in Washington, DC, starting with the 2014 elections. Vote as though your very lives and livelihoods depend on it. They do.

April 18, 2013 | Payment Options — For anyone affected, we now accept American Express and Discover cards in addition to Visa and Mastercard.

November 21, 2012 | Rebore Delivery Delay— Unfortunately, our friends out at Delta Gun Shop/Clearwater Reboring are extremely busy and have a large backlog of work at this time. Delivery of new projects, which include reboring barrels, are expected to take a minimun of 1 year.

November 1, 2012 | Social Media—Some of you may have noticed the addition of certain social media icons

to the footer of our website. Well, In an effort to be more user friendly we are attempting to post our more regular news and thoughts through social media. So for those who are so inclined, check us out on Facebook, Twitter, or subscribe to our RSS feed.

to the footer of our website. Well, In an effort to be more user friendly we are attempting to post our more regular news and thoughts through social media. So for those who are so inclined, check us out on Facebook, Twitter, or subscribe to our RSS feed.

September 1, 2012 | The Custom Revolver e-Book—As many of our customers may already be aware, the first edition of The Custom Revolver is completely sold-out. We have, however, painstakingly converted the first edition into an e-book. Please see the book section of our online store or Amazon.com for more details.

February 13, 2012 | TELEVISION APPEARENCE— Some months ago Bowen Classic Arms was privelaged to host Mr. Michael Bane and the crew from Shooting Gallery. Episode #151 "Full Custom" featuring Bowen Classic Arms is slated to premiere at 9:00pm EST on Wedneday February 15th, 2012 on The Outdoor Channel. Check your local listing for details, and more information can be found at Mr. Bane's website Downrange.tv or at Outdoorchannel.com.

December 12, 2011 | Price Changes— Much as we hate to do it, we must raise our prices on both parts and labor, effective January 1st. Some parts we produce have not sustained price increases since they went into production, in some cases, many years ago. Alas, events have overtaken us and prices from many of our vendors and suppliers, to say nothing of insurance, shipping and power providers along with hosts of others, have gone up, up and away. As the wise man so famously said "Son, you cain't make up them losses in volume.". We hope and trust our friends and customers will understand and bear with us. And, for God's sake, vote in November like your very lives and livelihoods depend on it.

December 11, 2011| RUGER REDHAWK IGNITION PROBLEMS— The Ruger Redhawk is the finest big-bore heavy-duty revolver available, combining the capacity for ultra big-bore calibers and sensible size. The great N-frame S&W, despite its refinement, grace and periodic updates over the years, simply isn't large enough or tough enough to handle the heavy .45 loads or the .475 and .500 Linebaugh rounds. The X-frame S&W is simply not a serious revolver due to extreme physical dimensions and weight. For all of its utility, however, the Redhawk has a Achilles heel in the form of weak ignition due to its unique main/trigger spring arrangement, firing pins and the transfer bar safety system. It is not unknown for box-stock, brand new guns to suffer from weak ignition in certain circumstances, even with factory ammunition. For a gun that is often carried afield as not only a primary hunting weapon but a back-up gun, this is a serious shortcoming and must be addressed.

The dual-action spring system, while ingenious, is often part of the problem since, to reduce felt single-action pull weights, owners have employed reduced-pressure mainsprings instead of tuning the sear surfaces for improved trigger action and weight. Using any sort of reduced mainspring in a standard Redhawk is inviting trouble. The Super Redhawk, on the other hand, has a separate trigger return spring which can be changed for a reduced-pressure part without jeopardizing actual ignition power through the hammer. For this reason, the Super Redhawks are viewed as more dependable and easier to tune. Properly handled, standard Redhawks will still tune very well but one should be mindful of the potential for ignition trouble and be especially careful.

There are several interrelated considerations. The usual industry standard (if there is indeed such a thing) for firing pin protrusion is around .050--.055. Few Redhawks will achieve this unless the transfer bar clearance in the hammer is minimized which will help. Even then, many simply don't have adequate protrusion Long firing pins will usually make up the difference and give guns dependable ignition. In rare instances, even this is not enough, no matter how close to minimum is set cylinder endfloat and headspace or how late the DA cycling drops the hammer. More spring tension is necessary. Bowen Classic Arms produces both 30# and 40# springs to replace the factory 20# part. While these springs rates may seem high, due to the compounding of leverage in the Redhawk action, this is necessary to achieve appreciable increases in hammer velocity. Even with the 40# spring, neither the single nor double-action modes will increase in weight a great deal and will be well within acceptable limits for field use. Some reduction in SA pull weight is possible with simple sear tuning typical of most proper tune-ups.

Unfortunately, there are known instances where even longer firing pins and heavy-duty mainsprings aren't the solution to ignition problems. Indeed, in these extreme cases, the problem is not really a matter of hammer power or firing pin length at all but rather a function of Ruger's transfer bar safety arrangement. Here is how to tell the difference: Classic 'light strikes', the traditional indices of poor ignition (out-and-out failures to fire or hang-fires)are usually manifest in the form of primer impressions from the firing pin that are deep and quite closely resemble impressions of cartridges that fired normally. Hard to tell them apart. On the other hand, cases where the transfer bar is short or partially retracted on firing, there may be just a faint dimple or a obviously shallower than usual firing pin impression. In this instance, there are a couple of problems with the transfer bar safety.

Ruger's transfer bar safety system is ingenious, effective and ordinarily dependable as a crowbar. It requires a somewhat different lockwork in single-actions but little else. The whole system consists of the single part, the transfer bar itself, working with other parts already in place even on guns without the system. There is a step in the hammer to accommodate the bar when the hammer is at rest and the bar retracted to prevent transfer of hammer force to firing pin. In the single-actions, there is usually little trouble unless a transfer bar breaks (only one such case ever observed at Bowen Classic Arms) or the firing pin head and transfer bar have some many miles on them that they are peened and battered to the point they reduce effective firing pin protrusion. This is a theoretical problem since no known examples of such failures have come to our attention. The Redhawk, on the other hand, has one firing pin difference that can allow wear and peening to the point use might cause a failure. Ruger single-actions which have a spring-loaded plunger in the base pin to push back on the transfer bar to enable it to ride up and over the firing pin without snagging it and tying up the gun. Since Redhawks don't have an provision to prevent this snagging, the firing pin is domed to allow the transfer bar to function smoothly and ride up and over the firing pin on cocking. As you might imagine the flat of the transfer bar is contacting only a point on the dome-headed firing pin and, in time, might peen a flat spot on the pin or a divot in the transfer bar or some combination of both. In either case, you have less firing pin protrusion. On Redhawks of more recent manufacture, this problem is exacerbated by a shorter transfer bar with a radius at the top to aid in bypassing the firing pin. In extreme cases, the flat face of the transfer bar doesn't get past the centerline of the firing pin and you can end up with a point contacting a line which dramatically increases the contact patch pressure and will accelerate wear with the usual predictable results on reliable ignition. But, alas, there is more.

Not all ignition failures in Redawks are traced to the gun. Some are traced to the shooter. The syndrome is often hard to diagnose. The Redhawk is a fairly heavy gun and often equipped with long, heavy barrels, especially in the Super models. It is difficult to hold up the gun (shooting off-hand) without a good bit of that weight laying on the side of the trigger finger. When the trigger is pulled, the finger lurches rearward a bit and, with the change in pivot point of the gun, the muzzle lurches downward which has the effect of pulling the trigger away from the trigger finger. When this occurs, the transfer bar is partially retracted BEFORE the hammer lands on the bar/firing pin. Depending on how much the transfer bar retracts, you may realize a failure to fire. If the firing pin strike in the hammer is just a small dent, this may be a shooter problem. Good shooting technique will help and often cure this. Never-the-less, the gun has still failed to fire in a relatively normally use situation. One way to diagnose this phenomenon is to shoot the gun off a rest. Chances are, problem won't occur. At this point, about all one can do is weld up and lengthen a transfer bar. This is a tricky last resort but should do the trick.

Our best advice is to shoot any Redhawk at least a couple hundred rounds with the ammo you plan to use before heading afield. In the unlikely event you experience any ignition failures, there are steps to take to correct the problems. With a little patience, you will have a peerless heavy-duty revolver.

June 1, 2011| Books Out of Stock — We are sorry to announce that The Custom Revolver is temporarily out of stock. We are currently engaged in procuring a reprint, and hope to be able to start shipping books again soon.

January, 2004 | Colt Bulletin— Traditional sources for Colt single-action revolver parts and hammer/trigger rebuilding vendors are increasingly unreliable and unable to provide us with timely, dependable service. In turn, we can no longer offer predictable delivery and the quality we require in our own work. Accordingly, we can no longer undertake repairs and restoration projects on Colt revolvers, particularly vintage guns. Further, getting parts, especially hammers and triggers, for late-model guns is increasingly difficult, if not impossible. In the short term, we will continue to offer our basic tuning package but only for unaltered 2nd and 3rd generation guns.

Where guns arrived with modified or damaged parts, we will advise their owners of the problem and request that the owner procure new replacement parts. If that is not possible or satisfactory, the gun will be returned at the owner’s expense. We are also dropping from our upcoming catalog the Flat-Top Target conversions and will not offer these even on a special-order basis because too many of the specimens submitted have proven to be so poorly fitted and finished that we cannot offer our best workmanship.

We regret the inconvenience but ask that our clients understand that we are in the custom pistolsmithing business and are not gunsmiths or blacksmiths. That said, we’ll do our best to recommend specialists who can attend to restorations and repairs. While we admire the pre-war Colt revolvers, for our purposes, the late-model United States Firearms guns are far superior. In terms of fit and finish, they have no equal and are the best vehicle for fine custom single-actions. In view of developments at USFA, it is entirely possible that, in the near future, we will no longer offer services and modifications for Colt revolvers of any stripe.

September, 2003 | Old Model Ruger Revolver Source — Old Model Ruger single-action revolvers were once plentiful as houseflies. But now, 25 years out of production and sought more and more by collectors, these guns are increasingly hard to come by. Which is not good news if you are seeking a suitable .357 Magnum for a .44 Special or .32-20 caliber conversion. Help is on the way.

Bill Hamm, Ruger Collector’s Association member and field representative, is an active collector and dealer in Ruger products of all sorts and, often as not, will be able to run down a nice non-collectible gun at a fair price to use in a custom revolver project. Few of us have the time or contacts to turn up guns on demand and, while Bill cannot conjure them out of thin air, chances are, if you give him a call, he’ll turn up something within a few weeks, if not sooner. Good guy to have on your side and if you see guns that might be of interest to Bill, let him know and help repay the favors.

Contact him at (423) 488-4866 or at BILL@GUNBLAST.COM

Written queries should be directed to P.O. Box 778, Harrison, TN, 37341

May, 2003 | Serial Number Placement on 5-shot Single-Actions — In the course of the last few years, we have encountered an increasing number of Ruger New Model receivers with poorly stamped or positioned serial numbers. The number is located under the cylinder window on the receiver’s right side towards the muzzle end of the cylinder. This is not a defect nor would it be a matter of any consequence were it not for 5-shot caliber conversions.

The cylinder window has to opened up slightly top and bottom to accommodate the oversize cylinders. This machine operation may whittle on the serial number if the number is stamped too close to the window or is stamped crooked, leaving even one of the numerals in the line of fire. Defacing a serial number is a no-no. Consequently, it is imperative that you examine your candidate gun before sending it to us to ascertain that the serial number placement is satisfactory and compatible with the pending modifications. This little sketch will show you what to look for:

The main thing is to have enough clearance between the numerals and the window. .030 is a questionable minimum. .04 – .050 is better, especially in terms of appearance. At any rate, paying some attention to this one detail will save all of us a lot of headaches and shipping costs. It is not convenient to have to hunt around for guns with good numbers but better safe than sorry. Feel free to call with any questions.